ConnectVend

This is Happy Ice's flagship machine: ConnectVend, is designed and used to connecting brand with customers

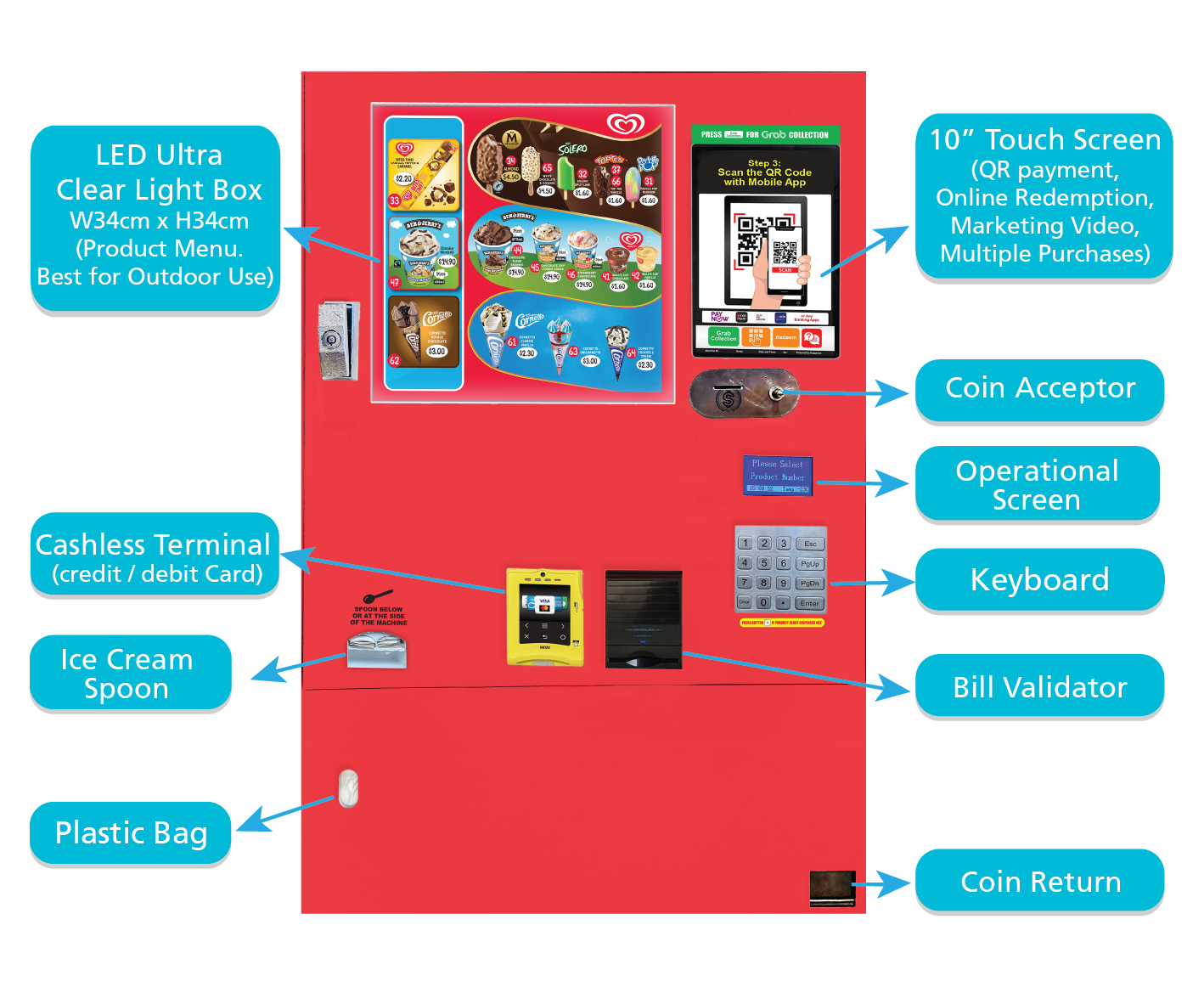

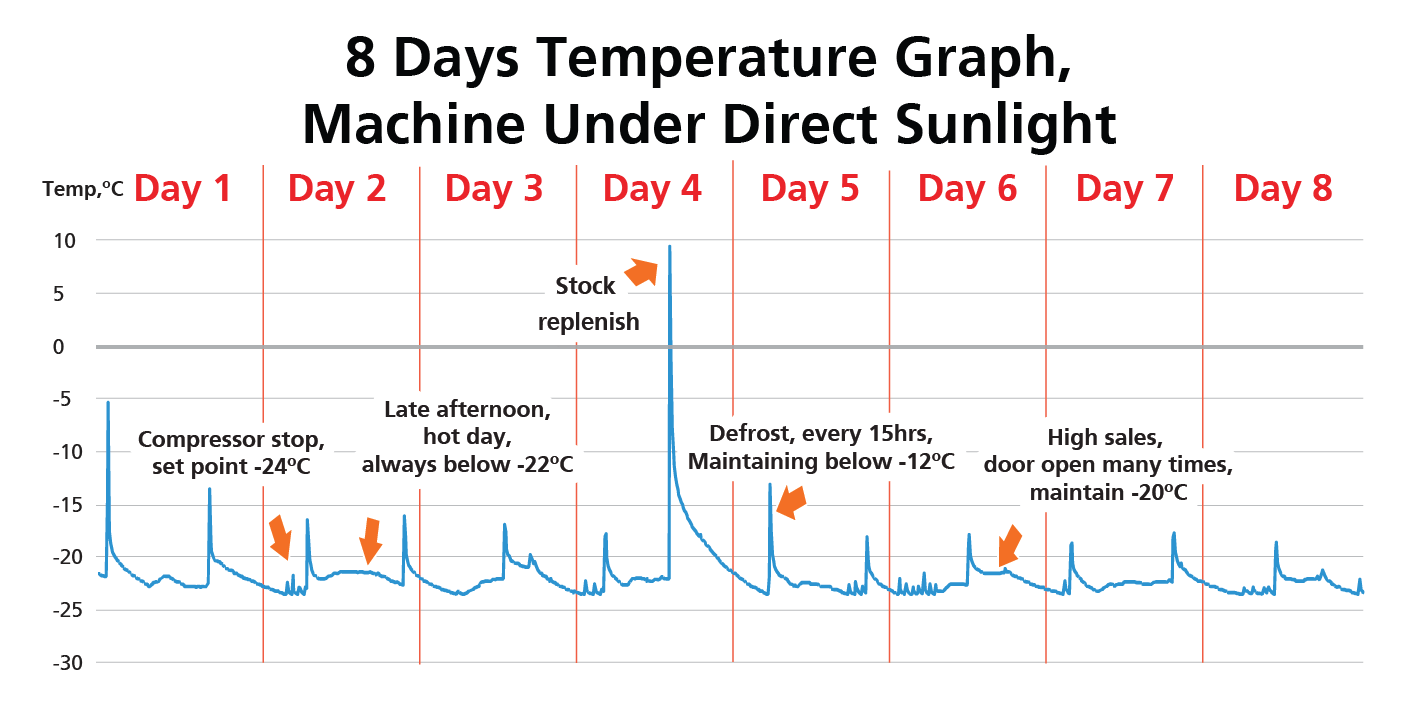

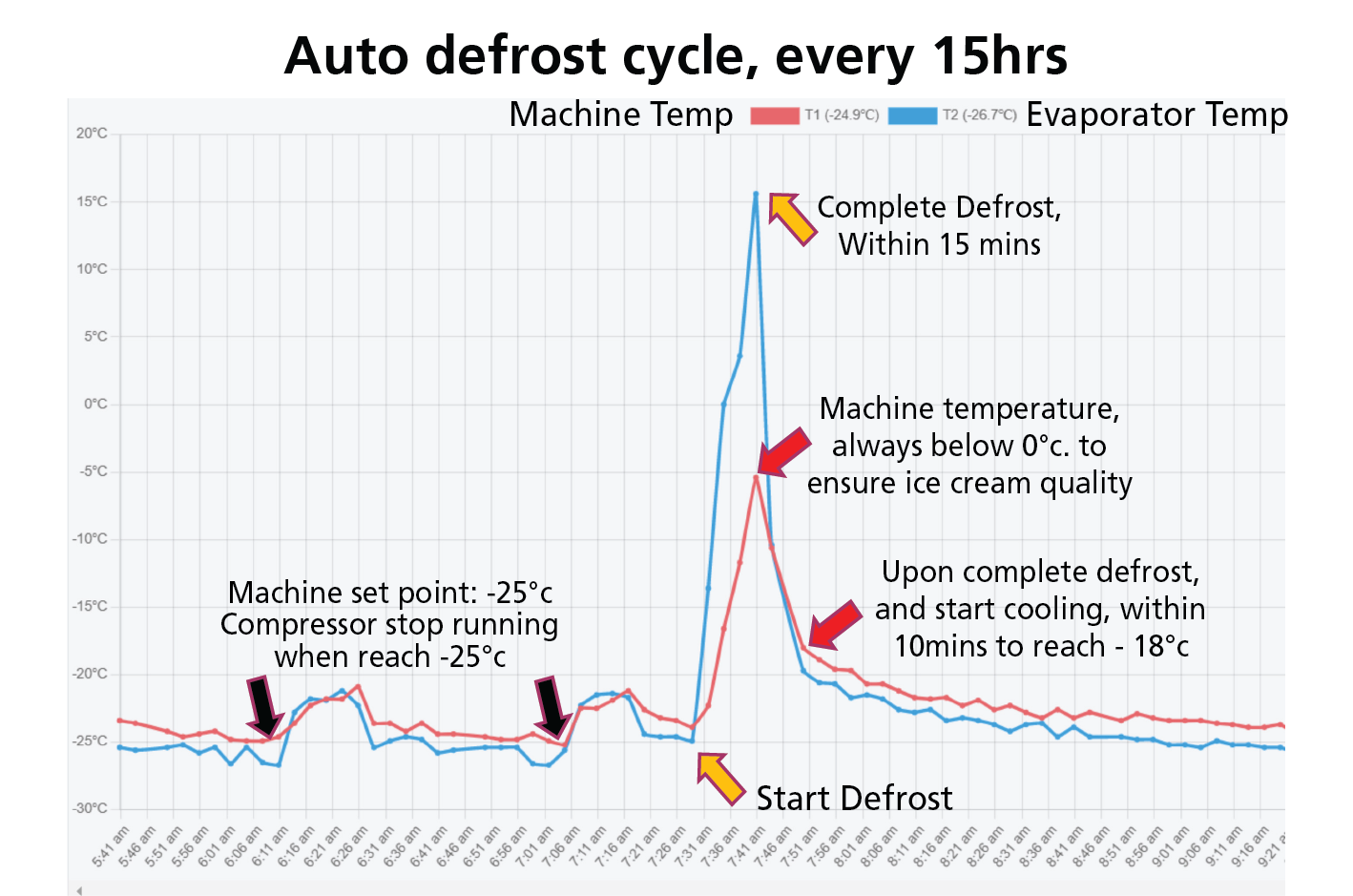

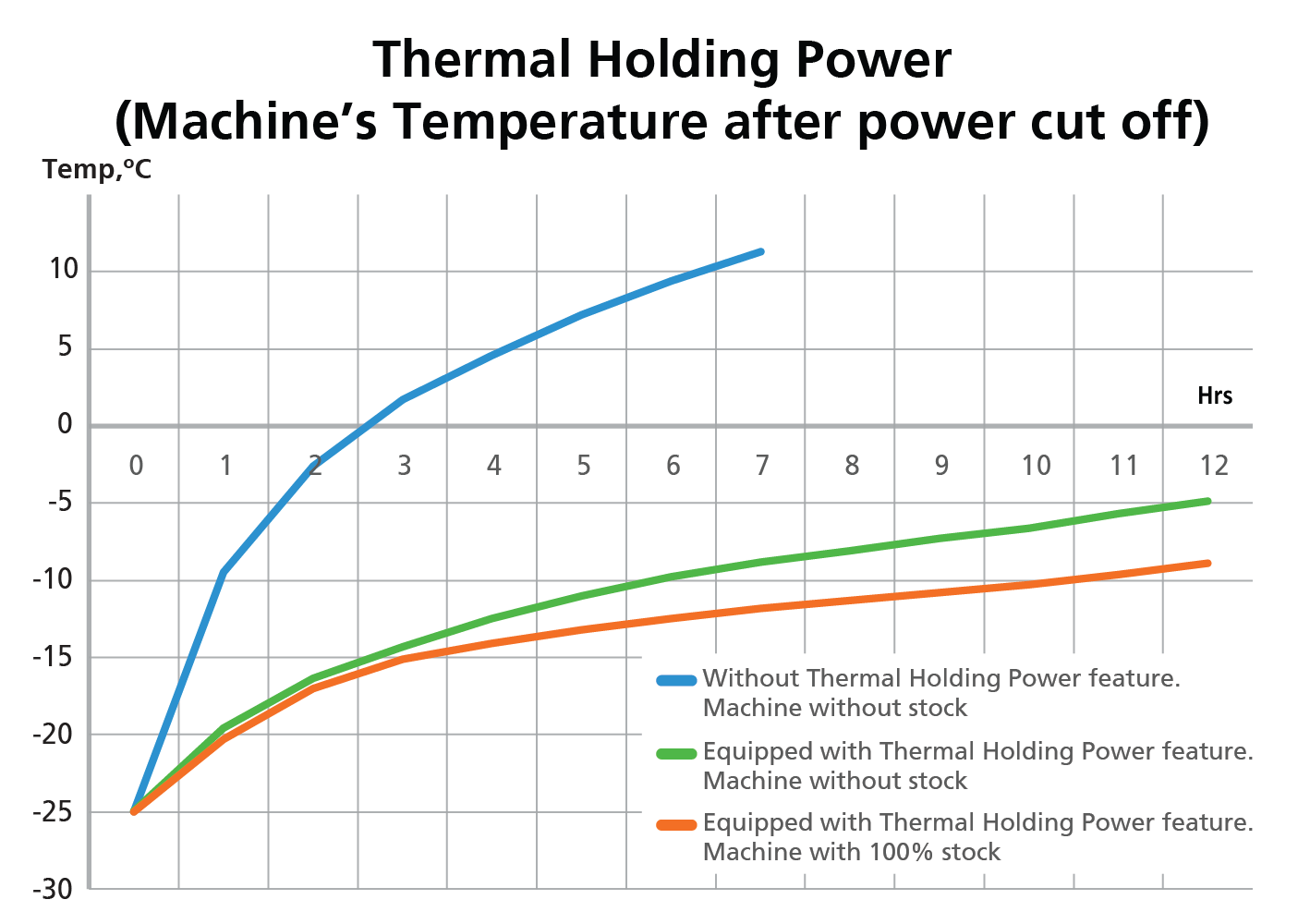

ConnectVend is special designed to work with the most stringent products: ice cream, to be operated at -24ºC. It can withstand outdoor tropical climate up to 43ºC. In the event of power disruption to the machine, the ice cream can be kept inside the machine for up to 12 hours, which gives operation team ample time to respond to the incident. The machine dispensing racking can also be customized to fit various frozen products sizes to the machine. We can dispense frozen product as small as a Popsicle stick to as big as a bento box.

Size (W x D x H cm): 72 x 90 x 198

Weight: 280 kg

SKU & Capacity: 12 SKU, 430 pcs

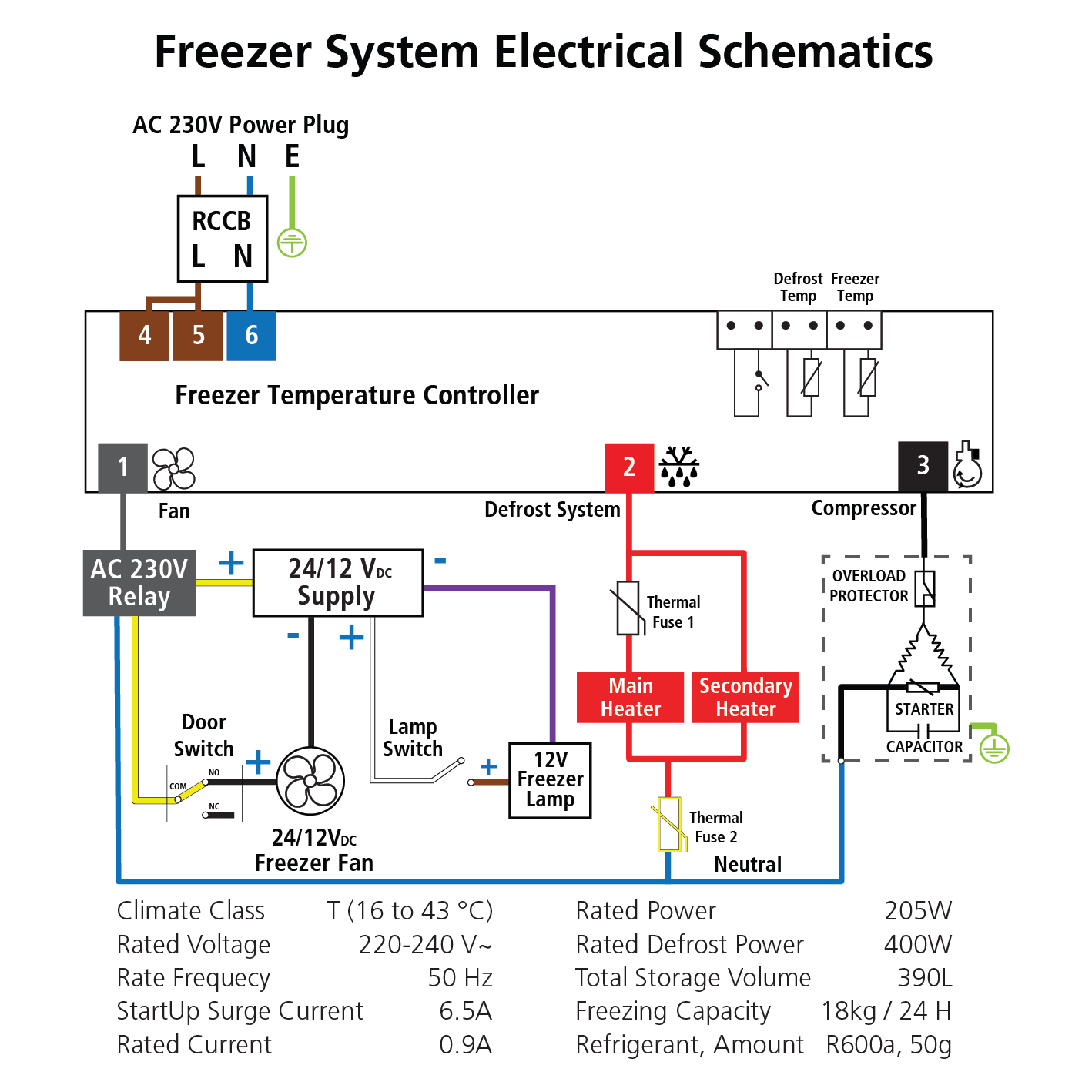

Rated Power: 200 watt

Thermal Holding Power: 12 hours

Operating Temperature: -24ºC

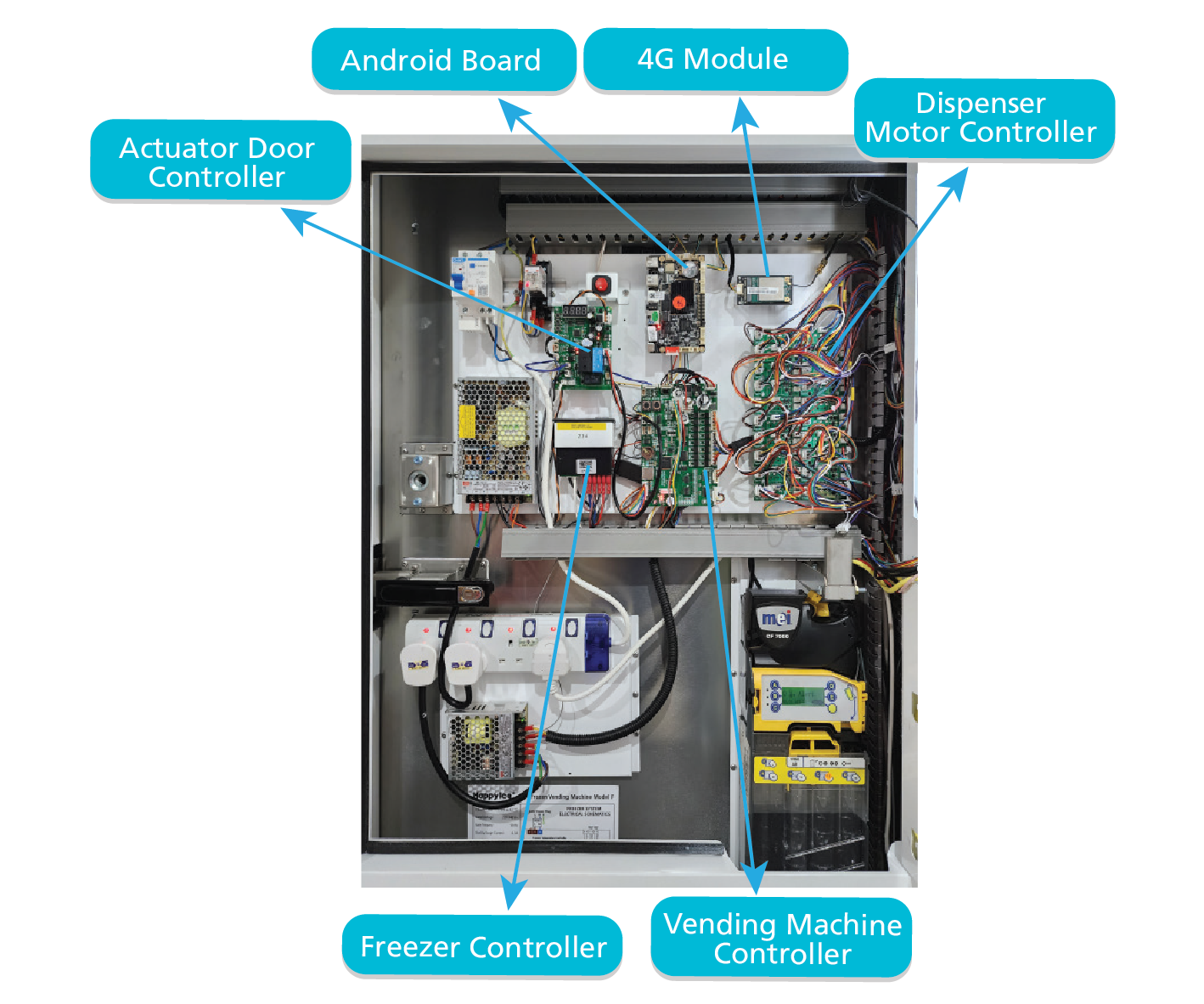

Remote Monitoring: Yes

Support Payment: Cash & Cashless

Dual Screen: W45 x H34 cm LED Light Box, 10” Touch Screen (QR payment, Online Redemption, Marketing Video)